Antimicrobial Peptoids & Surfaces

Page Content being updated September 2025

Page under construction…

With the increase of antimicrobial resistance (AMR) to conventional antibiotics new ways to fight microbial infections need to be found. Antimicrobial peptides (AMPs) show promising results, but their structure being directly derived from nature makes them vulnerable to rapid degradation. Peptoids aim to solve this issue allowing for antimicrobial results, while reducing biodegradation. As peptoids are mimics of peptides the antimicrobial peptoids are dubbed antimicrobial peptide mimics (AMPMs). The peptoids used contain a lipid tail, aiding in self-assembly, and Ethelyne glycole at the N-terminus of the AMPM helps further, without sacrificing antimicrobial effectiveness.

Many surfaces in different industries are affected by the built up of microbes, this is biofouling, and contributes to 40-70% of hospital-acquired infections. It also affects water purification, food packaging, and maritime operations. Here too can peptoids help by creating antifouling coatings.

Figure 1. Graphical representation of AMPMs. The activity and biocompatibility of Antimicrobial Peptoids can be enhanced by chain-end modifications

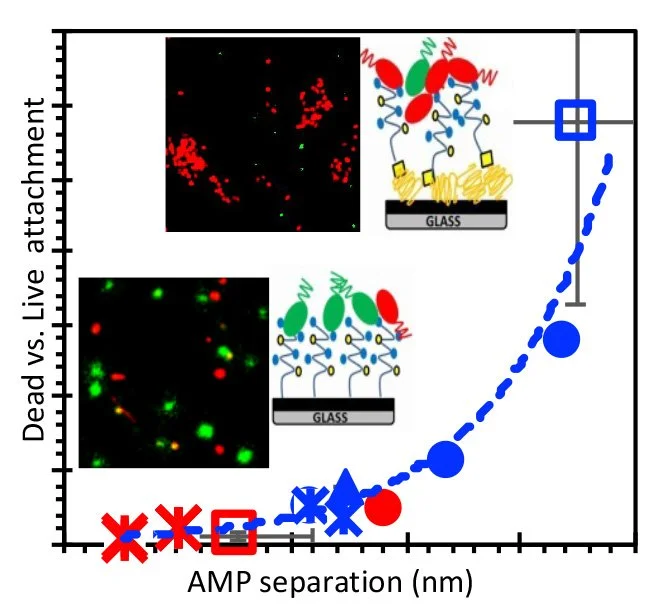

figure 2. Gaph showing that after surface attachment, activity of both antimicrobial peptides & peptoids are similarly controlled by their separation in the near-surface 3d space, determined by the grafting density and surface coupling approach.

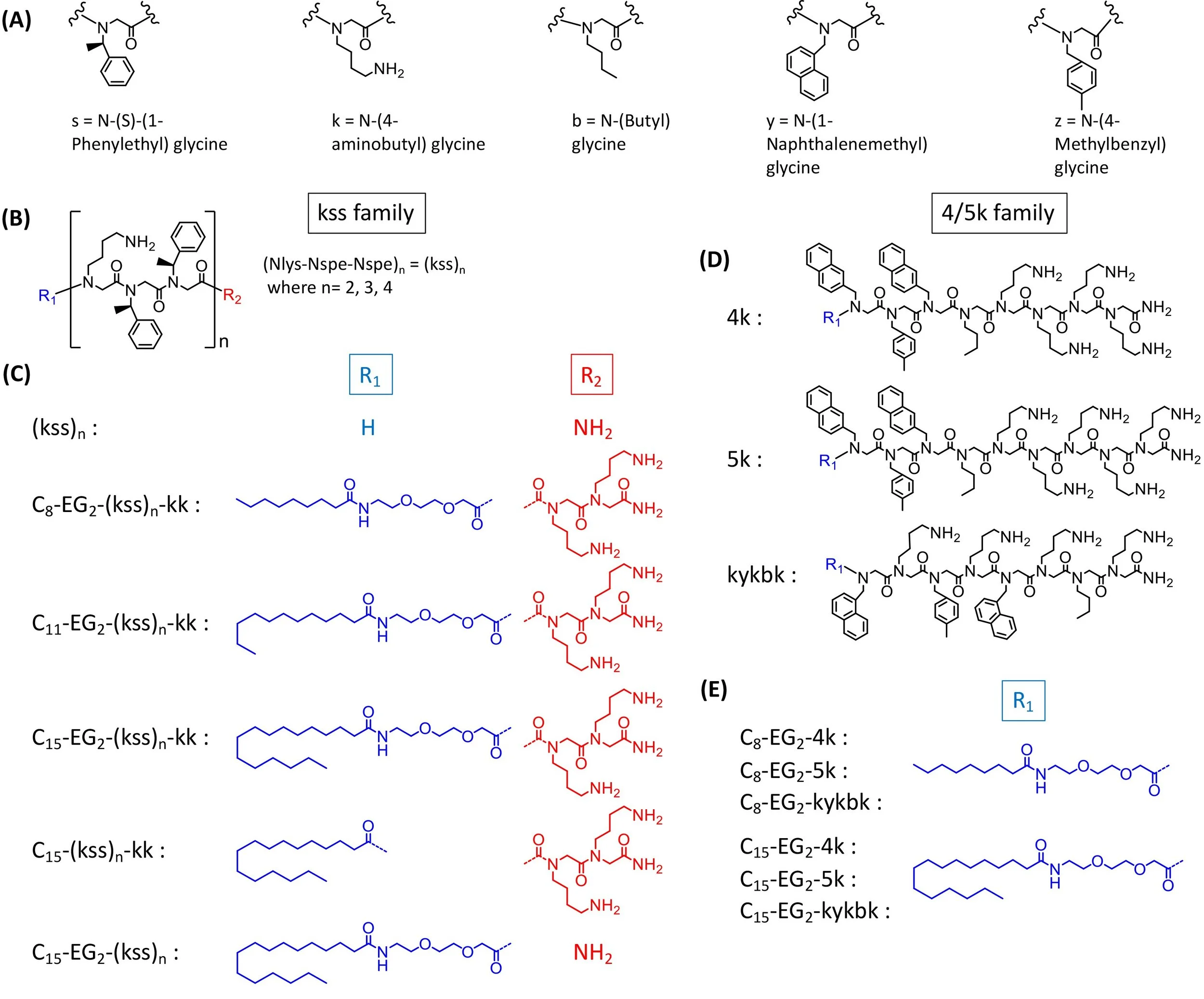

Figure 3. Graphic showing 2 families of AMPMs that are of interest, the kss family and the 4/5k family. (A) shows peptoid monomers used in these AMPMs. (B) shows the base of the kss family, with (C) showing the R1 and R2 chains in different kss species. (D) shows the 4/5k family, with (E) showing the R1 chain to different 4/5K species.